Rapid prototyping is the latest buzz in the manufacturing industry. It kept product designers and developers out-there in awe. Its benefits and sphere of influence spell bounds both small scale, medium scale as well as large manufacturing industry. In this rapid tooling method, physical objects are automatically constructed with solid freeform fabrication. All the process in product development are done with the assistance of software application. Sourcing this rapid tooling, prototypes are created quickly and its functionality, performance and output are tested. Major advantage of sourcing rapid tooling is, making new changes or modifications are simple and can be easily customized. This article would edify you more about rapid tooling.

Rapid tooling:

Product development is no single step and it also consumes huge money. Rapid prototyping lets the user to create a new 3D prototypes and assist the designer or developer to procure client approval. The final look of the product also obtained using this method. As the prototype has higher efficacies, it would be more helpful while sending them for client approval.

Identify flaws:

3D model lets you detect all the flaws and improvise them. But imagine the same with 2D paper-based prototypes, it is hard to fish out the flaws and it takes more time to make necessary changes. But things are simplified now. Making changes and customizing are simple now.

Conceptualization:

In this rapid tooling method, product designers can see the overall outcome of their design, product in its prototype view. The designer can pin point the flaws of the product and fix them while it is in the production process.

Customization:

Customization needs more time and money. But with rapid tooling, customizing becomes much simpler these days. It doesn’t need any special tools for customization and thus customization can be done under budget while sourcing rapid prototyping.

Efficacies:

The flaws in the prototypes are fished out in its manufacturing process and they are modified. Thus it increases the overall efficacies of the prototype as well as the product in the future. Increased efficacies always hikes the worth of product and designers can save some time.

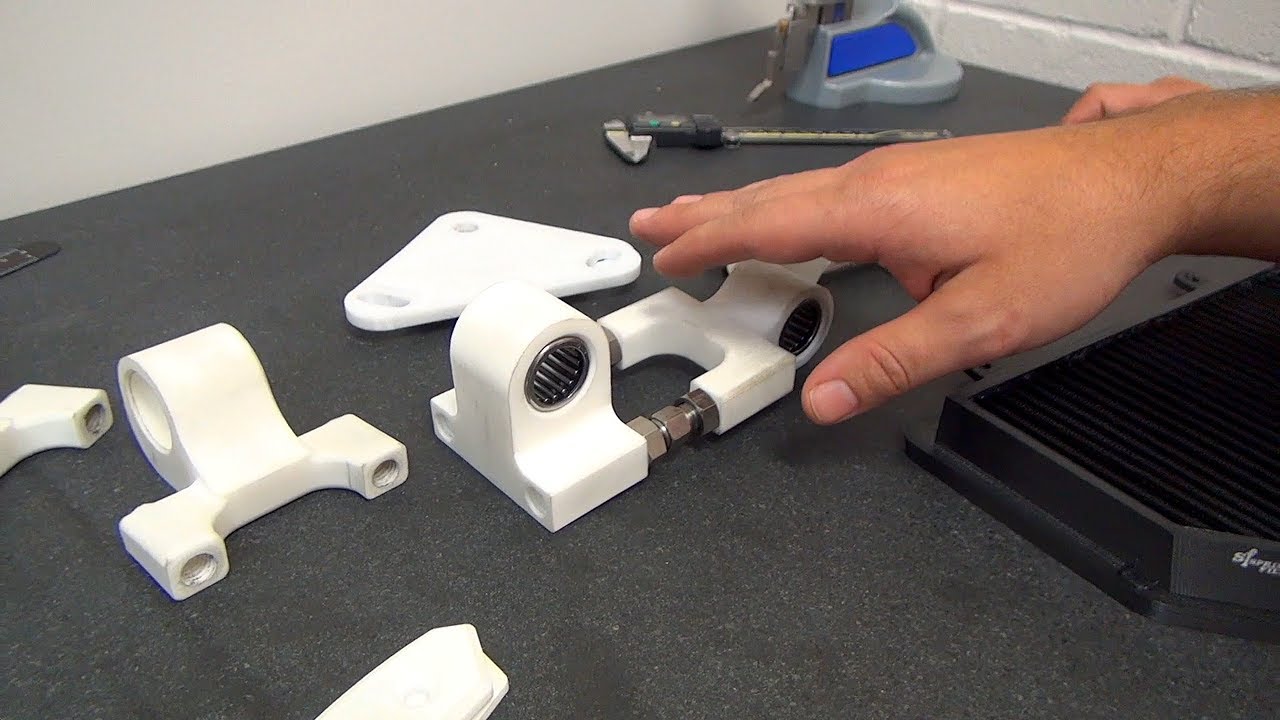

Two main things used in rapid prototyping is CAD program as well as 3D printing machine. It only requires minimal use of tools which is why the cost of product development is less in this method. So, using rapid prototyping is one of the best decisions you have made.

Once you have decided to get assistance of field experts to lend a hand in rapid prototyping, commence your research of fishing out the service providers. Internet is also a better place to start your research. Consider the years of expertise, various service they render, cost of hiring them, license and credibility before your hire them. The firm must pass all these steps of screening and do not forget to scrutinize reviews, testimonials on internet. Spending time on reviews, testimonials would give more ideas about the calibre of service they render and worth of investing your time over them.